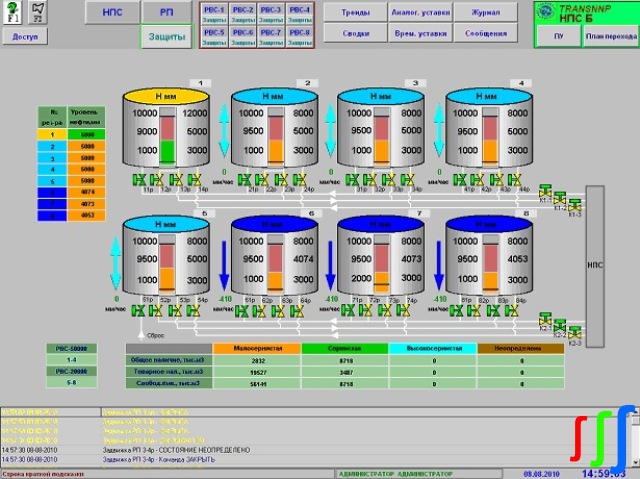

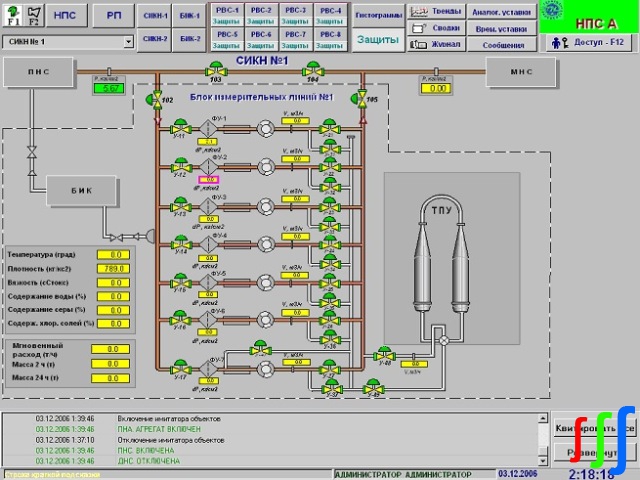

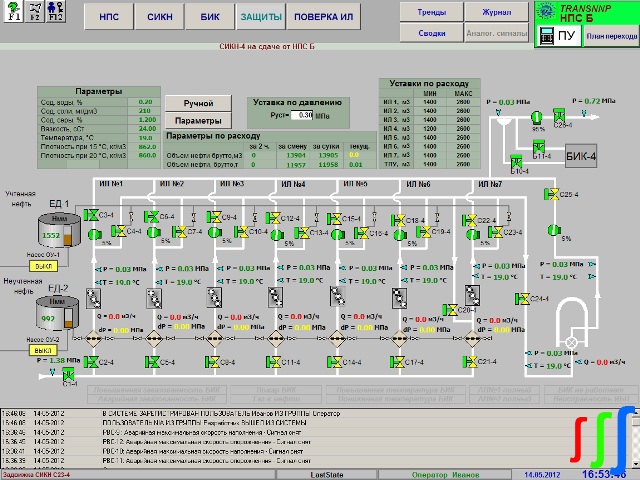

Simulator for training product handling operators

Purpose

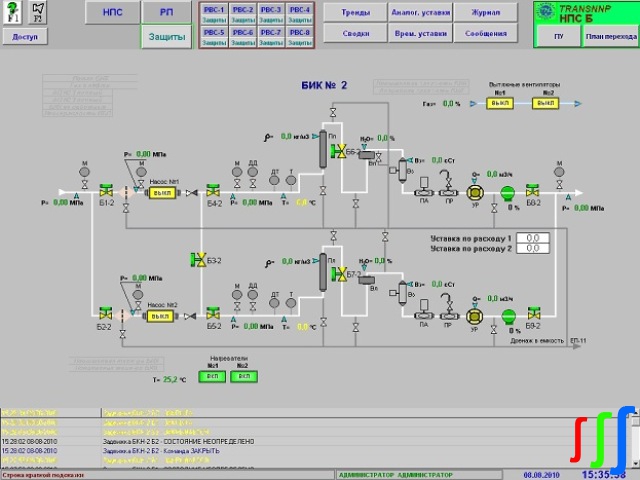

The simulator for training product handling operators and oil metering station operators (hereafter referred to as the training simulator) is intended for training product operators of product tank farms and operators of oil metering stations how to operate and control the technological equipment of tank farms and oil metering stations in normal and emergency conditions by using hardware and software packages of the microprocessor-based automatic systems as well as for training the operating personnel how to behave in and respond to emergency situations.

Components

The training simulator consists of 1 workstation for the instructor and up to 50 workstations for trainees. The workstations are connected into the local area network.

Description

The main functions the simulator performs are to:

- simulate the operation of:

- individual tanks and tank farms

- oil metering stations

- pumps

- shutdown valves, stop valves, gate valves & accessories equipment

- oil transfer between the oil and oil products pumping stations

- imitate oil level and oil quality parameters in each of the tanks;

- allow to set up initial conditions for the product operator work;

- calculate the analogue parameters (mass/weight, volume, pressure, levels, temperature, flow-rate, density/specific weight, sulfur content, etc.) and the discrete parameters in real-time.

If you have found a spelling error, please, notify us by selecting that text and pressing Ctrl+Enter.