Oil leak detection system simulator

Purpose

The leak detection system simulator is intended for the initial training of the oil transport operators and dispatchers how to work with the leak detection system. It helps them acquire skills in the process flow control and develop an idea of the technological process in general and its distinctive features in particular. It helps them gain knowledge about possible standard and non-standard situations when actual leaks are automatically detected in the linear pipeline sections. The simulator also helps the operating personnel develop good skills and response behavior patterns when leaks are detected.

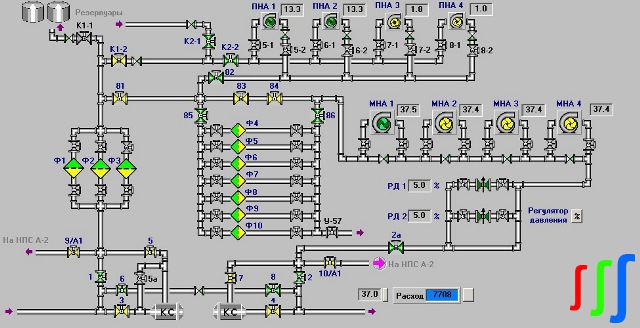

Components

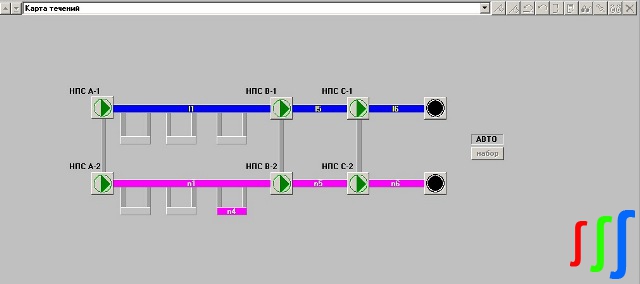

The simulator works together with the dispatcher simulator and (or) the operator simulator and can be deployed not only as separate automated workstations but also as the automated workstations incorporated in the simulator complex as component parts.

Description

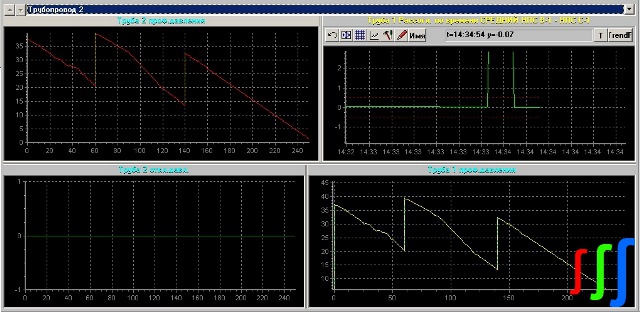

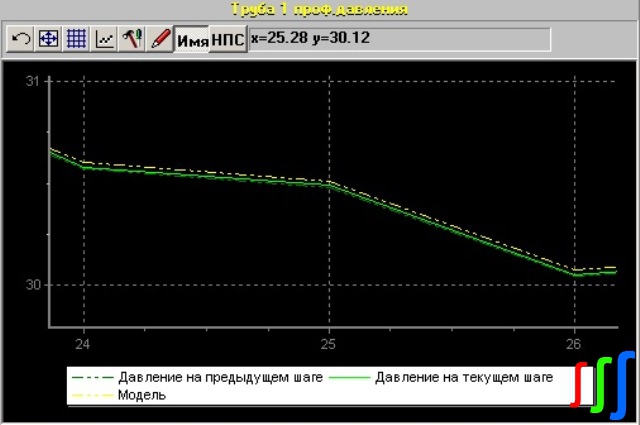

The simulator is based on the operation principles of a parameter-oriented leak detection system and a pressure-wave-oriented leak detection system.

The main functions of the leak detection system simulator are to:

- indicate seal failure or leakage or break of airtight seal in the oil trunk pipeline;

- detect the location of leakage or seal failure in the oil trunk pipeline;

- determine the time when leakage occurred;

- determine the leakage volume.

If you have found a spelling error, please, notify us by selecting that text and pressing Ctrl+Enter.